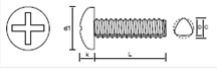

Trilobate screws cylindrical head cross phillips

DIN 7500-C - UNI 8112 - ISO 7045

The trilobed self-tapping screws have the characteristic of forming the thread during their assembly. Materials: CARBONITRIDING STEEL - INOX A2 AISI 304 - INOX A4 AISI 316 - INOX AISI 410 - INOX AISI 430 - ALUMINIUM.

Read moreTrilobular screws, also known as self-forming or self-tapping screws, are fasteners designed to form their own thread directly into non-threaded holes.

These screws are defined by DIN 7500, which establishes the specifications for self-forming screws with metric threads. Compliance with DIN 7500 ensures that the screwing process takes place by plastic deformation (without chips) and that the resulting internal thread is a standard metric thread, guaranteeing a highly reliable fastening and the possibility of reuse.

Thanks to their special three-lobed section geometry, they allow for precise, stable, and play-free coupling between the screw and nut, ensuring high mechanical strength and vibration resistance.

They are widely used in the automotive, electronics, mechanical, and household appliance sectors, where secure, repeatable, and durable fastenings are required.

During screwing, the three lobes of the shank plastically deform the material of the hole, creating an internal thread perfectly compatible with standard metric screws.

This particular design:

Milanoviti trilobular screws are available in numerous configurations:

Trilobular screws are widely used in:

Thanks to their ability to form a precise metric thread, they are ideal for all applications requiring a secure, reusable, and high-performance fastening.

Consult our technical catalogue to identify the most suitable screw. For quotation requests, attach the code or technical specifications and send them to: info@milanoviti.it. Our technical team is available to support you in choosing the ideal fastening solution.

They are self-forming screws with a trilobular shank that creates a thread in the hole material without producing chips. Ensuring a stable and durable fastening, they differ from self-tapping screws by offering greater precision and repeatability in tightening.

Self-tapping screws cut the material, while trilobular screws elastically deform it, generating a more precise thread with higher resistance to loosening.

They also allow the subsequent use of standard metric screws in the same hole.

Yes, a pilot hole is required, with a diameter and depth suitable for the type of screw and the material to be assembled. The correct hole size is essential to avoid excessive tightening torque and ensure a perfect thread.

Our technical department is at your disposal to help you define the correct hole dimensions.

Trilobular screws are suitable for:

Yes, in many applications. Since the thread is formed by plastic deformation rather than cutting, the screw can be removed and reinstalled multiple times while maintaining a secure hold.

The most common configurations include:

With Phillips cross, Pozi cross, 6-lobe, cross-slot combi, and 6-lobe combi drive options.

Trilobular screws are available in:

The main parameters are:

Upon specific request, our staff can guide you through all the details for ideal operating conditions.

You can send a request to info@milanoviti.it specifying:

Our technical and sales staff will get back to you shortly with a tailored quotation.

Yes, we offer: